Intelligent Industrial Ecosystems

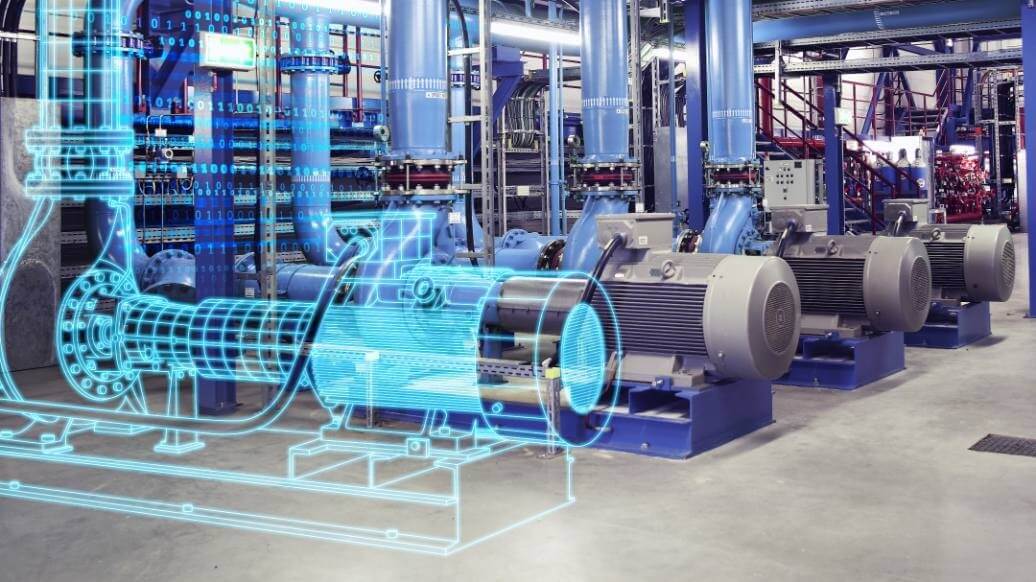

We Turn Assets into Connected, Future-Ready Systems

Digitalization is not just adding sensors: it’s capturing the right data, interpreting it, and turning it into decisions that reduce failures, costs, and uncertainty. Our goal is to transform traditional operations into intelligent, efficient, and real-time monitored ecosystems.

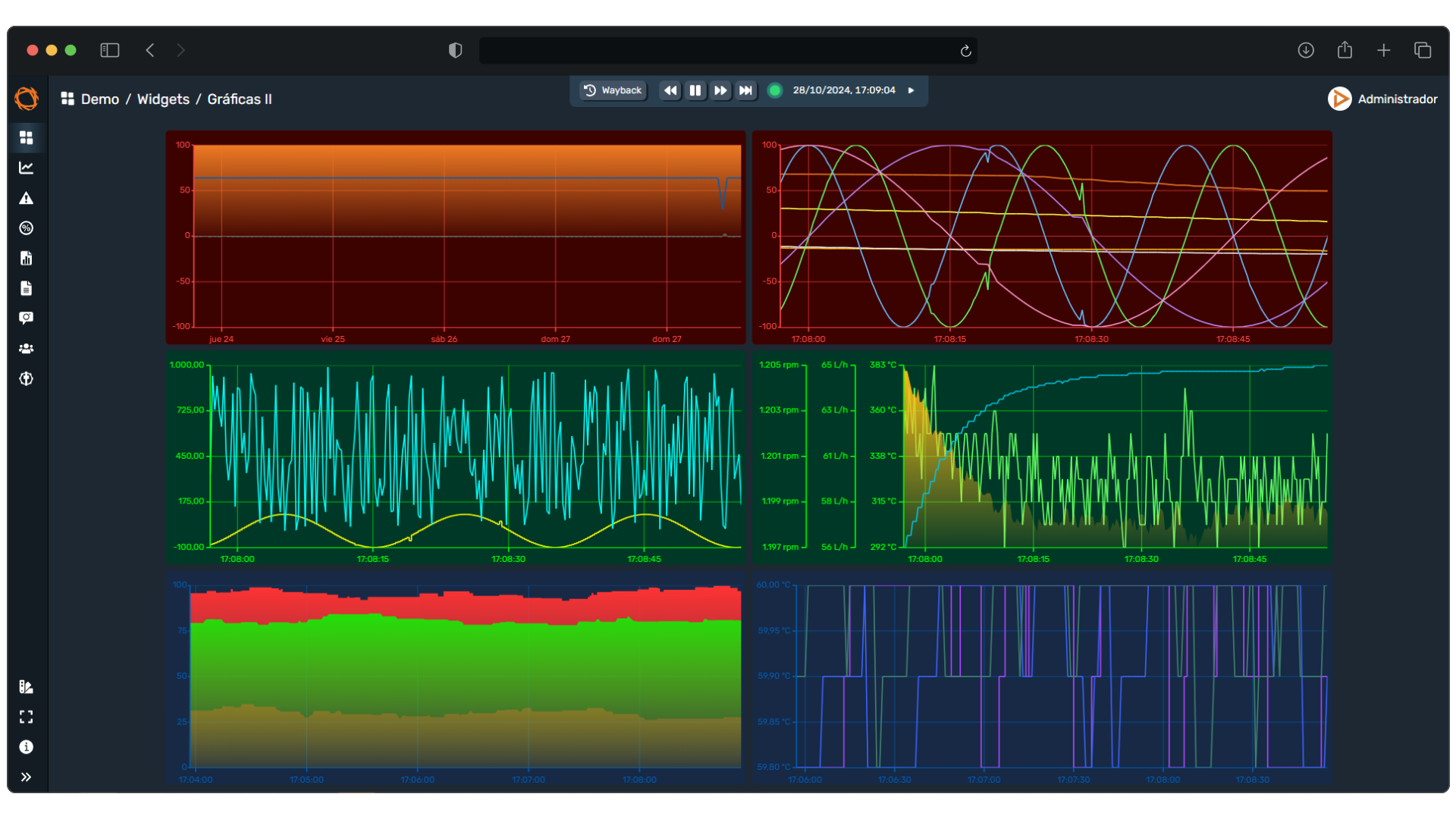

Real-Time Monitoring

Control your assets with accurate data, smart alerts, and continuous visibility of operational status.

Efficiency and Energy Savings

Reduce consumption, optimize resources, and minimize unnecessary maintenance through advanced analytics.

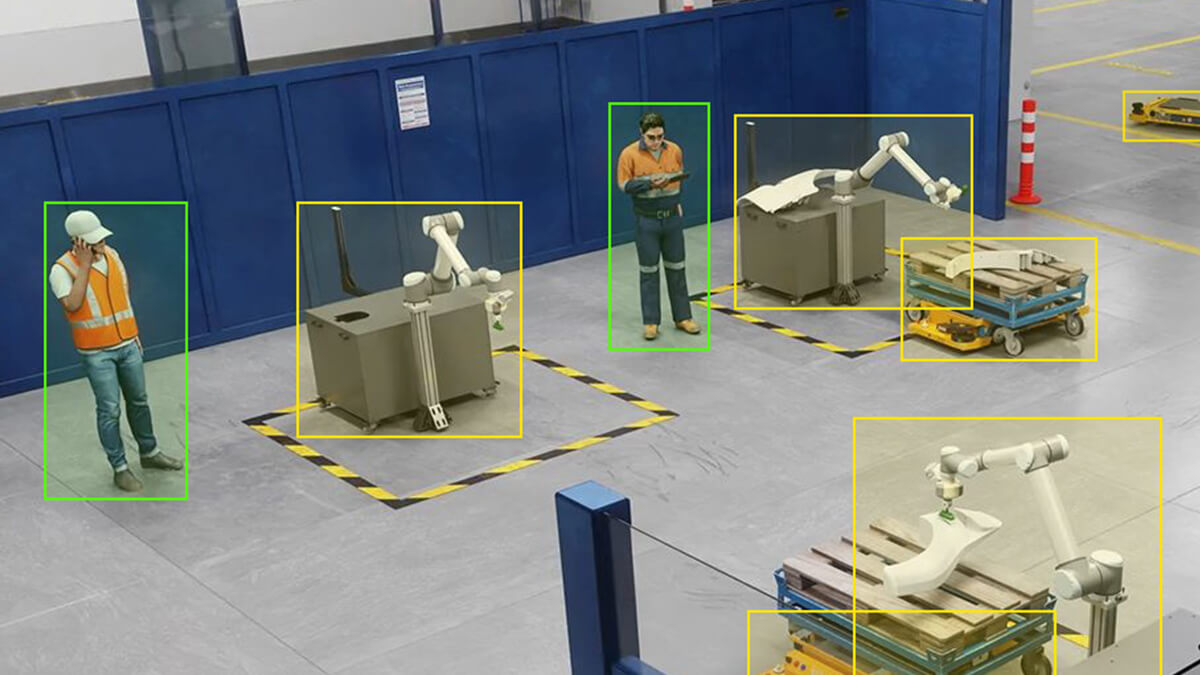

Safety and Critical Availability

Anticipate failures and operational risks in infrastructures that cannot afford downtime.A Modular Ecosystem That Adapts to Your Plant, Not the Other Way Around

Digitalization only works when it coexists with existing technology, delivers immediate value, and scales without redoing systems. At Surcontrol, we integrate equipment, protocols, and processes without interrupting your operation.

01.

No Friction with Existing Technology

Seamless integration with PLCs, SCADA, industrial protocols, and legacy systems without stopping production.

02.

Designed for the Technical User

Interfaces tailored for operators and engineers, without unnecessary complexity or rigid processes.

03.

Measurable Value from Day One

Fewer stoppages, greater traceability, real cost reductions, and visible improvements in operational efficiency.

04.

Guaranteed Scalability

An open, modular system that grows with your business without disruptive migrations.

Global Reference

Why Leading Organizations Choose Us

From concept to turnkey execution, we help you take real control of your assets through a modular and open ecosystem.

User Adaptation

Digitalization integrates seamlessly without complicating operations, making daily work easier for the technical team.

Compatibility with Existing Systems

Coexists with current technology without interruptions, avoiding downtime and extra costs.

Value and Scalability

Delivers clear metrics: reduced consumption, higher availability, full traceability, and allows scaling without changing systems every few years.Real Benefits of Digitalization

In a world where every second counts and efficiency is everything, companies face a challenge: the lack of real-time visibility into their assets, processes, and operations. Scattered data, alerts that arrive too late, and decisions made blindly result in lost time, money, and opportunities. With digitalization, you position yourself in a unique and unbeatable place that provides multiple advantages.

01.

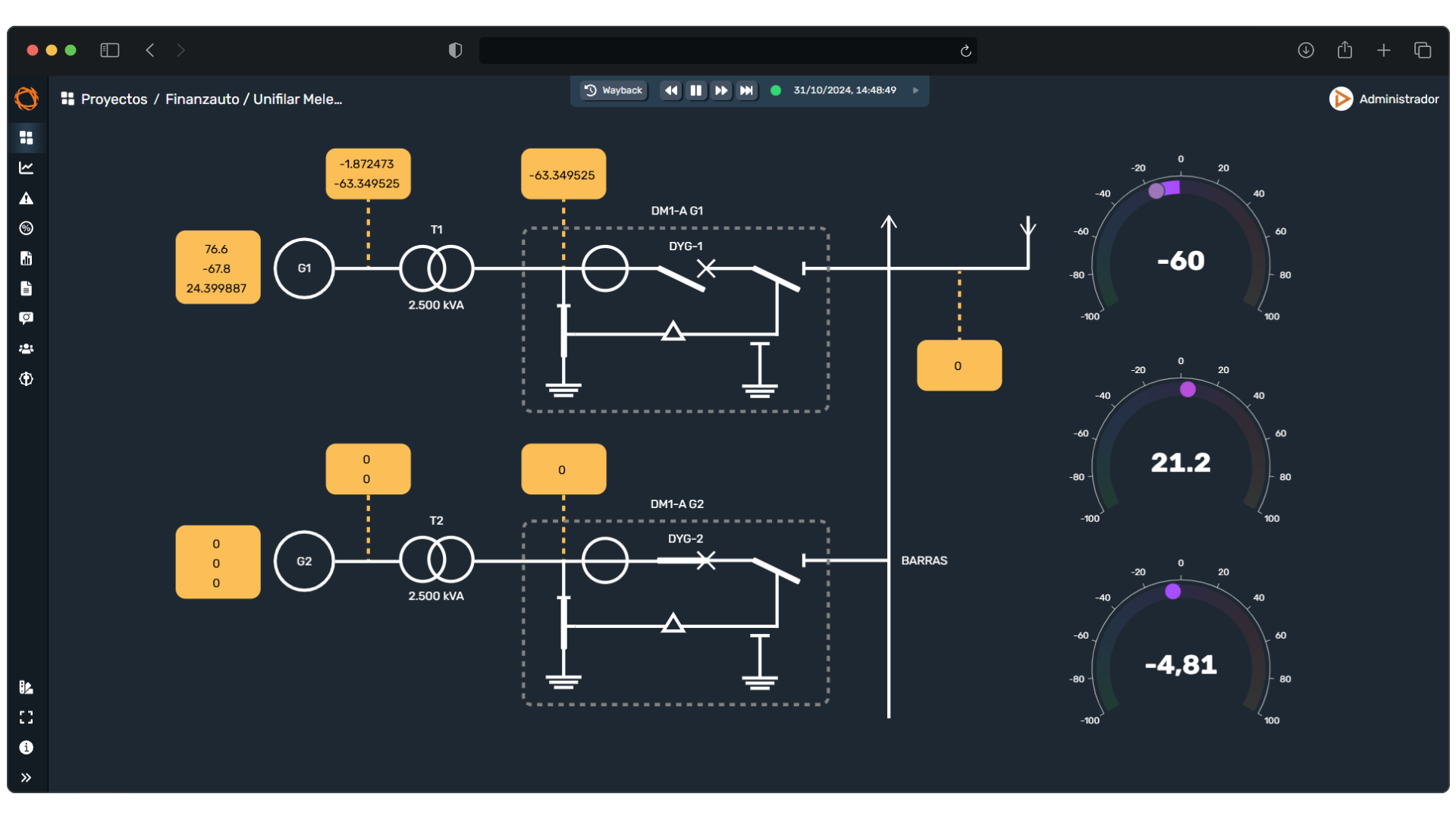

Total Asset Visibility

Gain a complete, real-time view of the status of your equipment, processes, and infrastructure, eliminating blind spots and reducing operational uncertainty.

02.

Fewer Downtimes and Unexpected Failures

Detect anomalies before they become breakdowns. Drastically reduce downtime and avoid unplanned interruptions.

03.

Energy Savings and Continuous Optimization

Analyze consumption, identify inefficiencies, and adjust the operation of your assets to sustainably reduce operational and energy costs.

04.

Traceability, Audits, and Enhanced Safety

Access complete historical data, record all events, and strengthen safety in critical infrastructures, facilitating audits and regulatory compliance.

Real Use Cases

Our Digitalization Solutions

Each solution is designed to deliver immediate value, optimize processes, improve efficiency, and ensure the safety of your operations.Elevator Fleet

Digitalization of the elevator system, implementing multiple digital twins that allowed real-time visualization of each unit’s status. Panels were configured to facilitate anomaly detection and instant assessment of each component’s performance. Automated generation of customized reports for each incident provided the team with a clear view of every event. View Case DetailsContact

Contact us at any time to receive more information about our products, services, solutions, and technical support.

This is what will happen next:

Needs analysis

We will contact you to understand your requirements and assess opportunities for improvement in your operations.

Action plan

Our team of specialists will work closely with you, offering recommendations and solutions to optimize the productivity and efficiency of your business.

Final proposal

We will provide you with a detailed action plan, including costs, delivery times, and a complete overview of the improvements it will bring to your assets.