Industrial Integration

Solutions that maximize the lifespan and performance of your assets

We analyze existing facilities, identify issues and design end-to-end solutions. Our approach avoids unnecessary replacements, optimizes operational continuity and reduces costs.

Comprehensive diagnostics

We assess machinery, processes and equipment across all industrial areas to identify root causes and determine the optimal solution.

Integration and automation

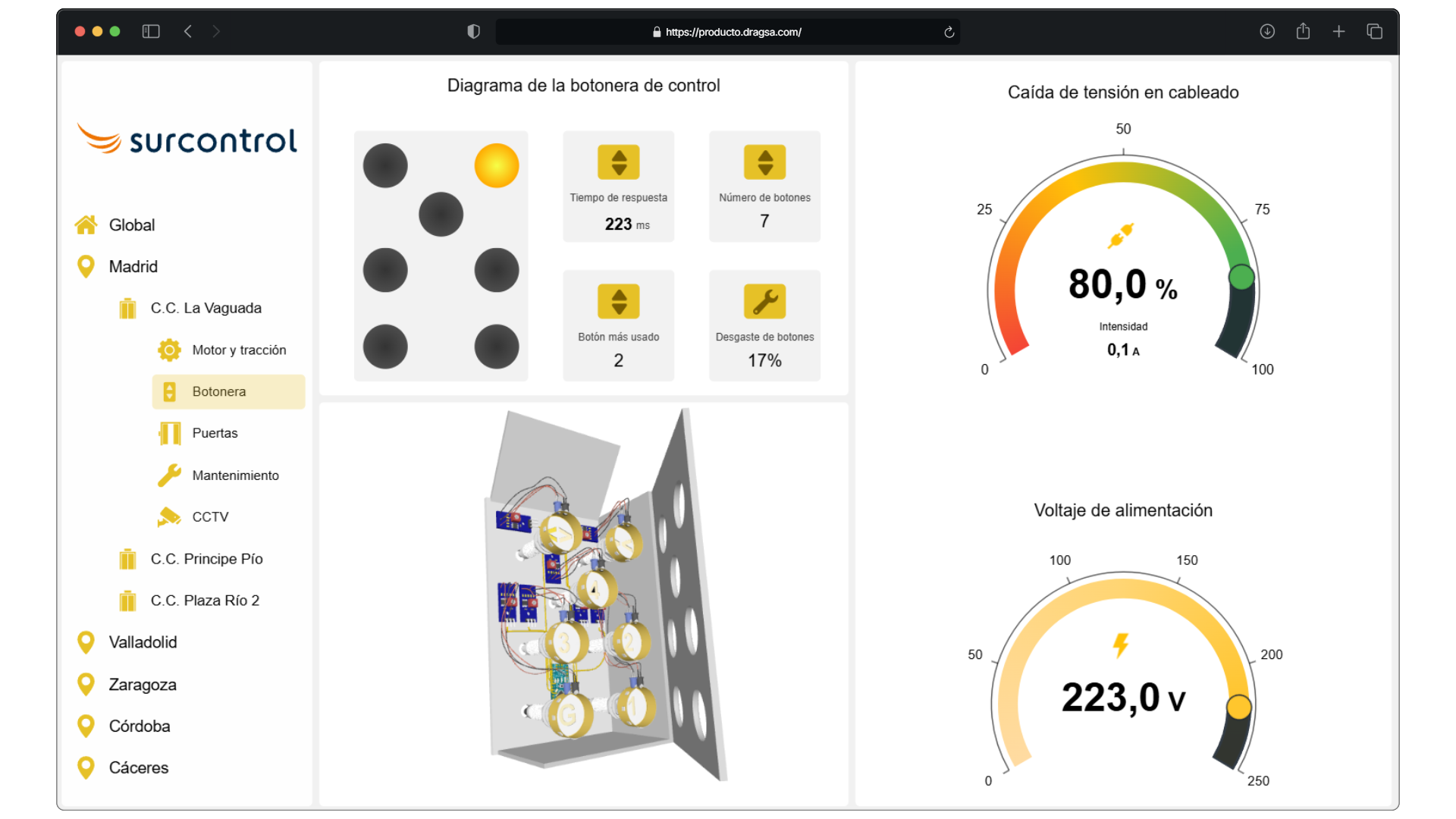

We unify industrial equipment, PLCs, SCADA, sensors and legacy systems to achieve a smooth, connected and secure operation.

Operational continuity

We ensure operational continuity in critical environments and complex regulatory frameworks by combining intelligent maintenance and specialized technical support.Industrial engineering, integration and automation

We deliver turnkey services covering design, integration, sensorization, automation and energy optimization. Each project is tailored to the sector and the technical requirements of each facility.

01.

Design and planning engineering

Development of customized solutions including drawings, simulations, process analysis and equipment selection to ensure a robust project from the outset.

02.

System integration and control

Process automation and integration of PLC, SCADA, IoT and industrial protocols to achieve a fully connected ecosystem.

03.

Process automation and integration of industrial systems

From sensorization and electrical cabinet manufacturing to commissioning and communication systems, all managed by a single expert team.

04.

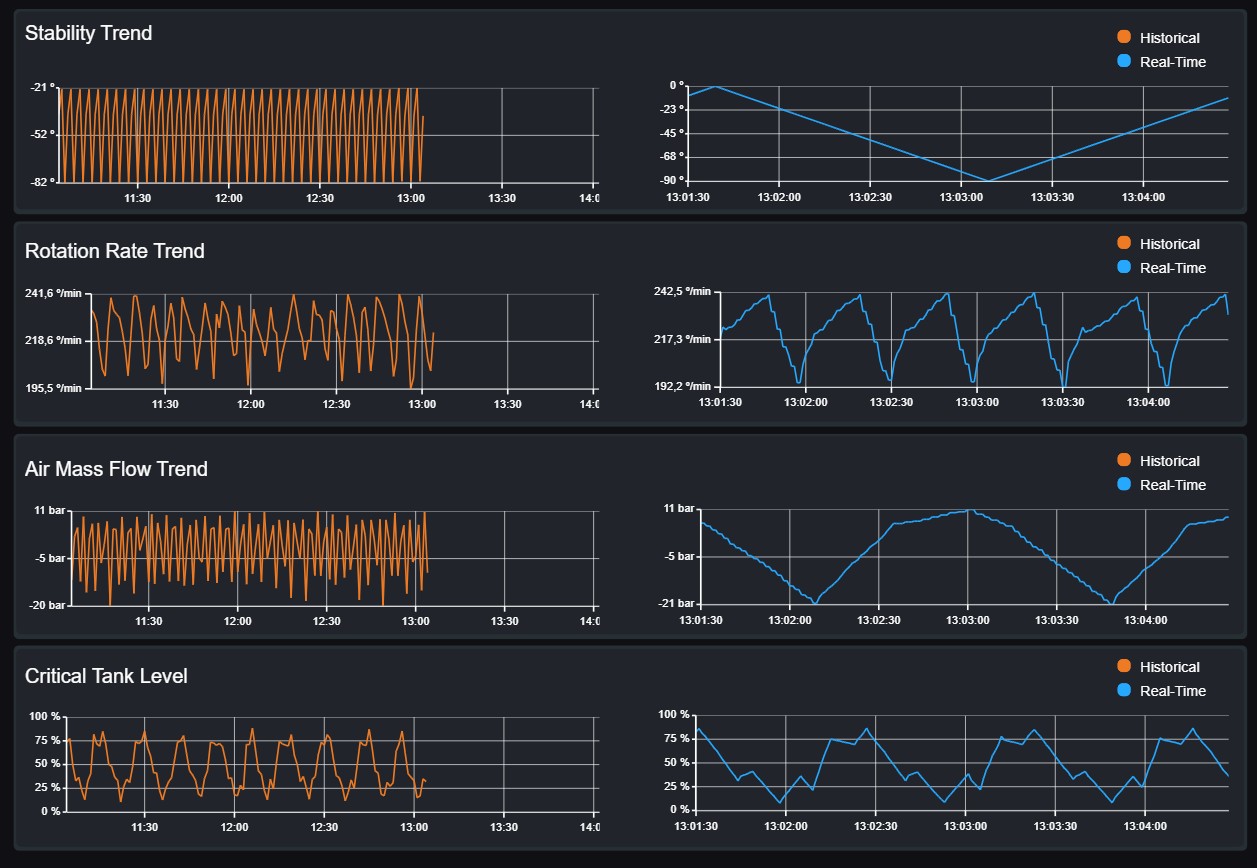

Maintenance and predictive engineering

Data-driven strategies that enable failure anticipation, downtime reduction and maximized asset availability.

05.

Process optimization

We analyze energy efficiency and operational flows to identify improvement opportunities, reduce consumption and maximize performance.

Industrial Reliability

Industrial Maintenance and Integration

We ensure the availability of your critical systems through preventive, predictive and corrective maintenance, as well as upgrades and improvements to industrial software and hardware.

Preventive and predictive maintenance

Real-time monitoring and analysis to anticipate failures and reduce unplanned downtime.

Rapid corrective maintenance

Agile interventions that minimize disruptions and ensure operational continuity.

System upgrades and improvements

Optimization of industrial software and hardware to keep your facilities efficient and secure.Contact

Contact us at any time to receive more information about our products, services, solutions, and technical support.

This is what will happen next:

Needs analysis

We will contact you to understand your requirements and assess opportunities for improvement in your operations.

Action plan

Our team of specialists will work closely with you, offering recommendations and solutions to optimize the productivity and efficiency of your business.

Final proposal

We will provide you with a detailed action plan, including costs, delivery times, and a complete overview of the improvements it will bring to your assets.