Intelligent Industrial Welding

The Challenge of Welding a Ship

Every weld is critical: tight spaces, complex geometries, vibrations, almost nonexistent traceability, and a shortage of qualified welders. Production teams know: excellence depends on people who are increasingly hard to find, and naval industry quality standards are becoming ever more demanding. KLUH offers an autonomous, safe, and efficient solution.

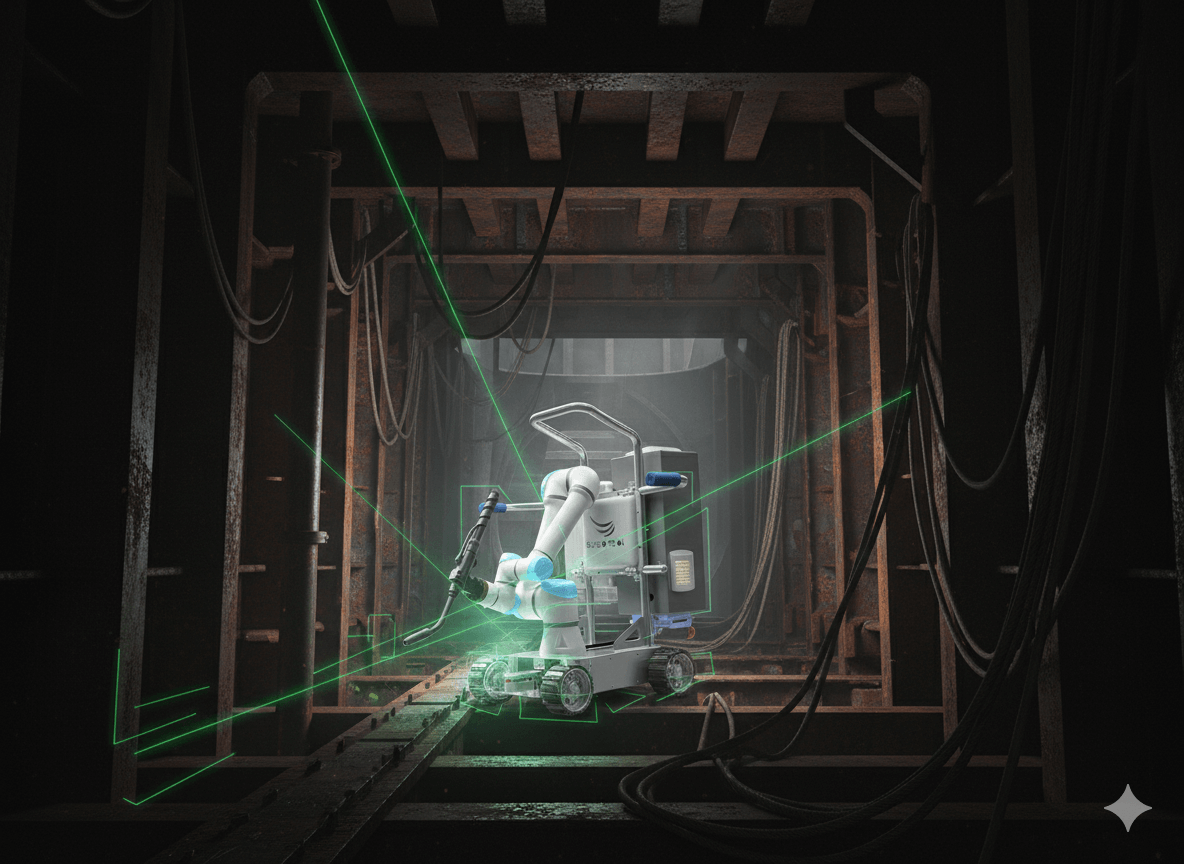

Omnidirectional Mobility

Mecanum wheels and laser sensors enable millimetric movements in any direction, providing access to hard-to-reach areas of the hull.

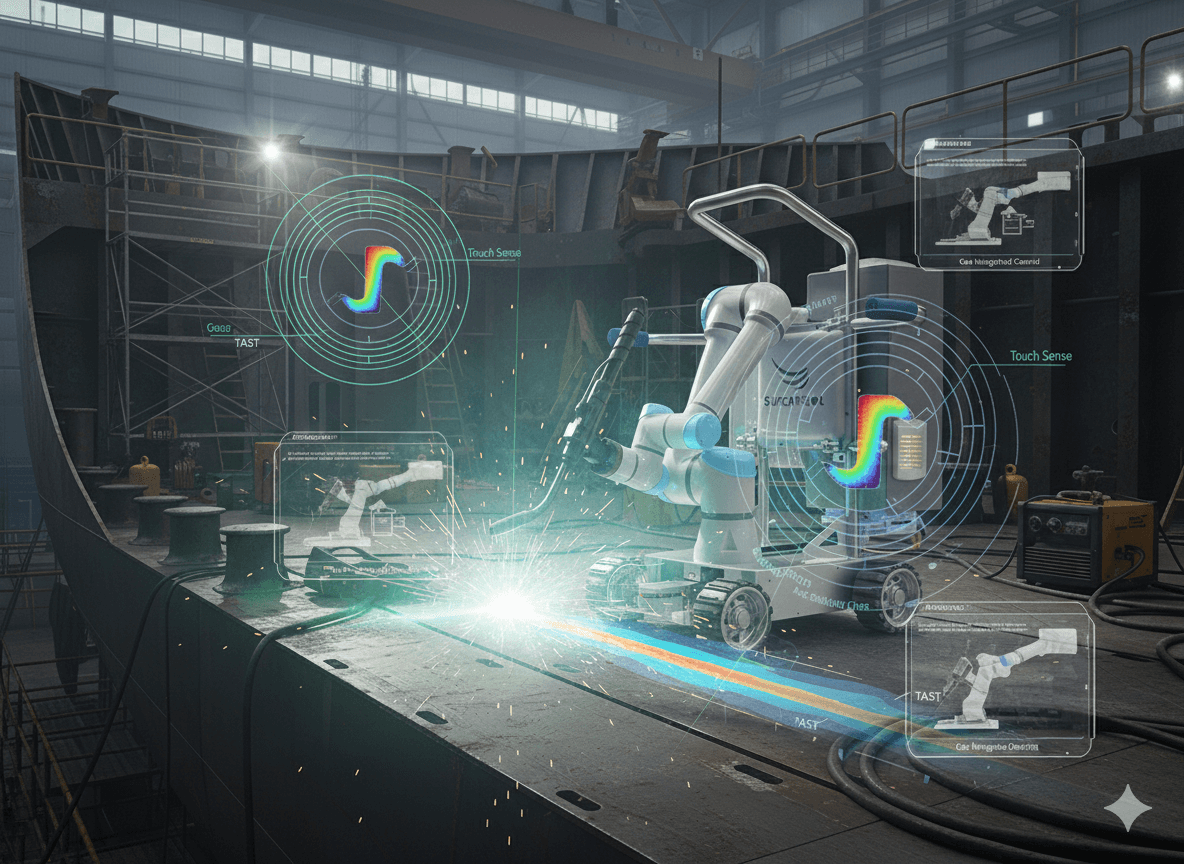

Guaranteed Weld Quality

Touch Sense, TAST, and integrated gas control ensure uniform and repeatable welds.

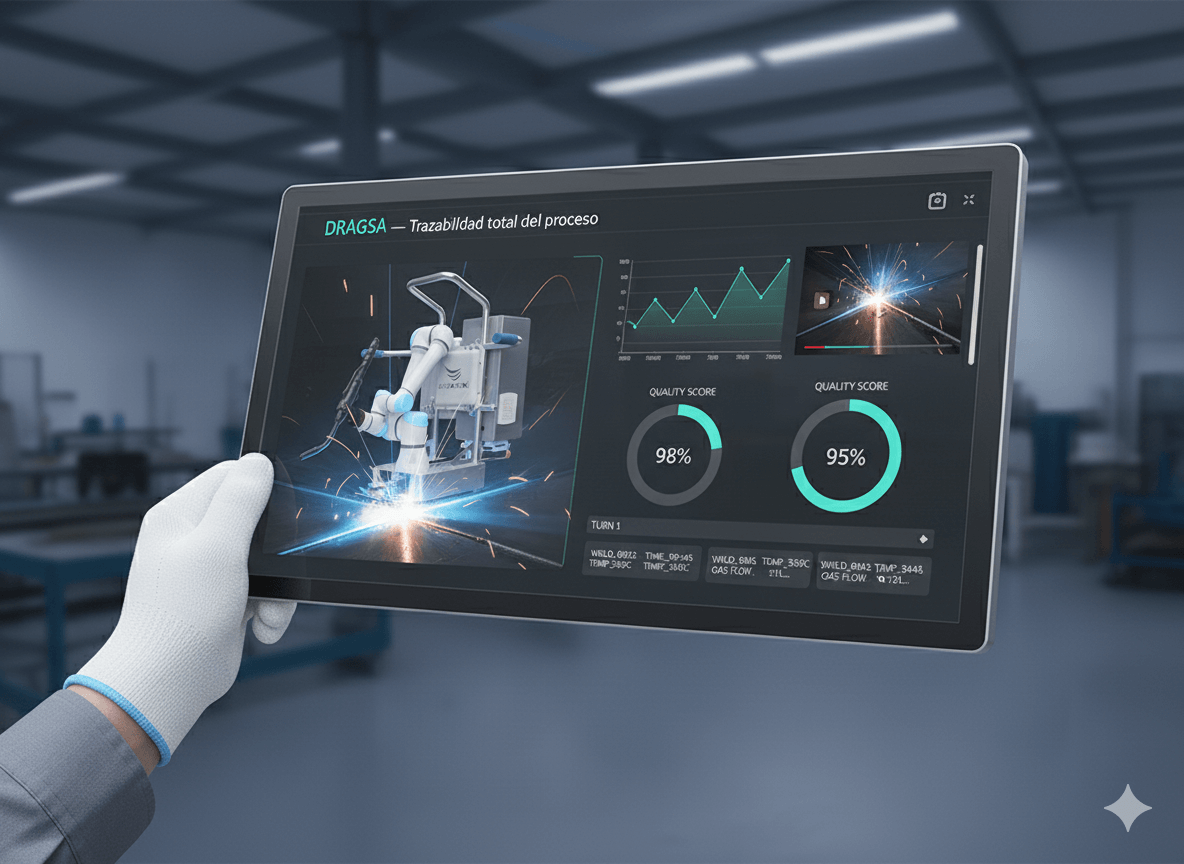

Remote and Safe Operation

The robot enters hazardous areas while the operator supervises from a tablet, avoiding fumes, electric arcs, and awkward positions.Complete plug & play platform

KLUH integrates robotics, 3D vision, portable mobility, intelligent software, and full traceability. It enables supervision of multiple robots, boosts productivity, and guarantees certifiable quality.

01.

Challenging spaces and changing geometries?

Automatic adjustments and stable weld bead execution.

02.

Productivity multiplication

A single operator can supervise up to 5 robots.

03.

Industrial safety

Operator kept out of hazardous areas; sensors and exclusion zones.

04.

Full traceability

List_4_DesC

05.

Reduced downtime

Optimize operations with instant repositioning, simple parameterization, and continuous performance that reduces errors and costs.

Advanced features

KLUH Tour: How It Works

Automatically detects profiles, adjusts the welding path, and allows macro configuration without programmers, multiplying productivity and reducing errors.

Intelligent detection with 3D Vision

Sub-millimetric scanning, point cloud generation, automatic identification of the weld profile, and automatic path adjustment.

Macro-based configuration

Joint database, editable and traceable macros, intuitive interface, no programmers or robot specialists required.

Centralized multi-robot control

Supervision of up to 5 robots simultaneously from a tablet, with automatic synchronization and remote stops.

Autonomous positioning in confined spaces

KLUH moves where a human would struggle, thanks to its mecanum wheels with proximity and laser sensors, enabling smooth and millimetric movements while avoiding collisions.

Advanced robotic welding

Weld quality no longer depends on human steadiness. KLUH incorporates top-tier industrial functions: Touch Sense, TAST, integrated gas control, and collision detection.

DRAGSA — Full process traceability

The quality evidence required by shipyards, certification bodies, and inspectors: parameterized history of every weld, including graphs, videos, and comparisons across parts and shifts.Contact

Contact us at any time to receive more information about our products, services, solutions, and technical support.

This is what will happen next:

Needs analysis

We will contact you to understand your requirements and assess opportunities for improvement in your operations.

Action plan

Our team of specialists will work closely with you, offering recommendations and solutions to optimize the productivity and efficiency of your business.

Final proposal

We will provide you with a detailed action plan, including costs, delivery times, and a complete overview of the improvements it will bring to your assets.