Advanced naval digitalization

Full control of shipyards, operations, and fleets

Automation and digitalization make it possible to address the lack of specialized talent by ensuring that critical processes are executed with precision and safety. From block fabrication and assembly in shipyards to propulsion system monitoring and predictive maintenance on vessels, technology acts as a true force multiplier.

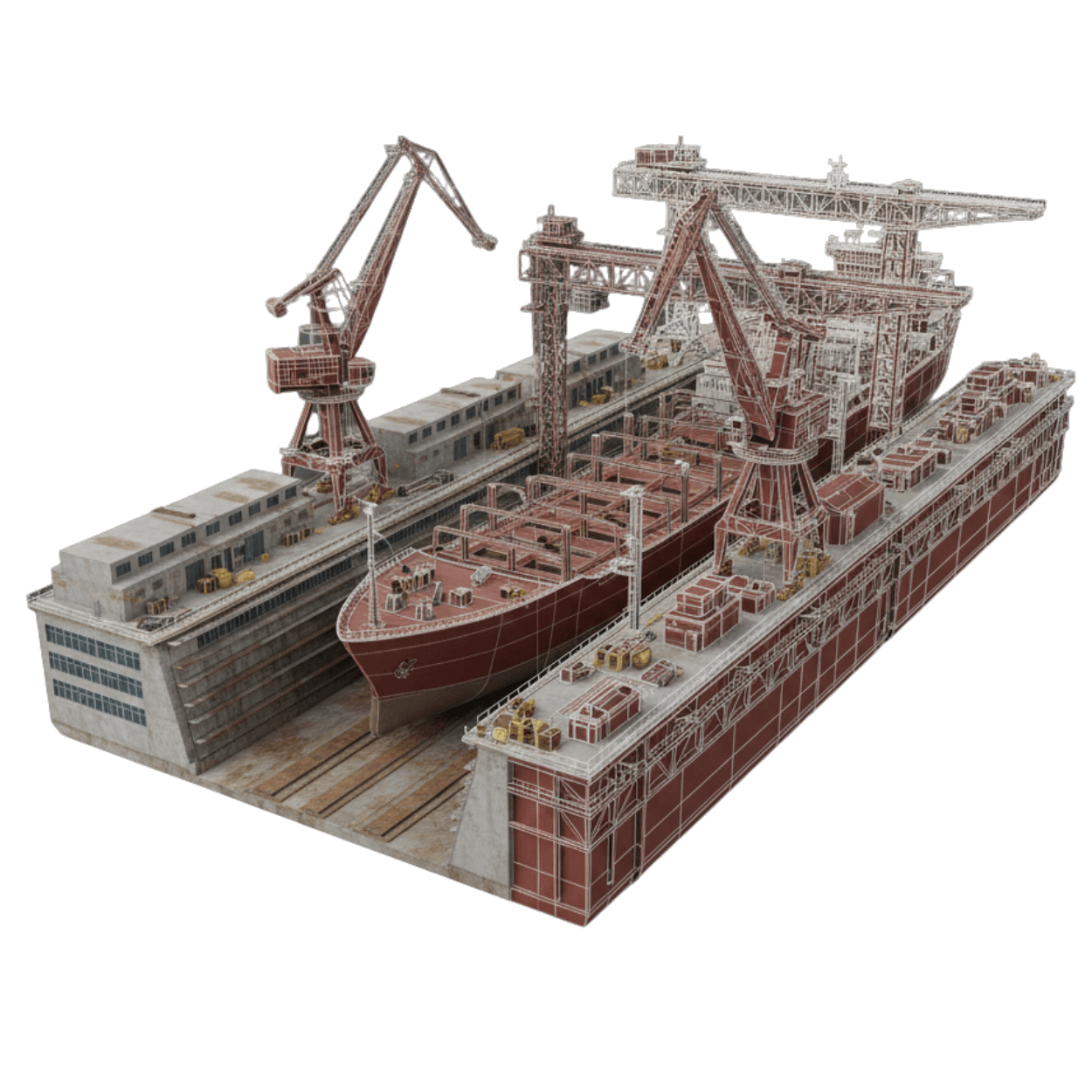

More efficient shipyards

Monitoring of assemblies, consumption, internal logistics, and critical machinery to anticipate delays, coordinate teams, and document every project phase.

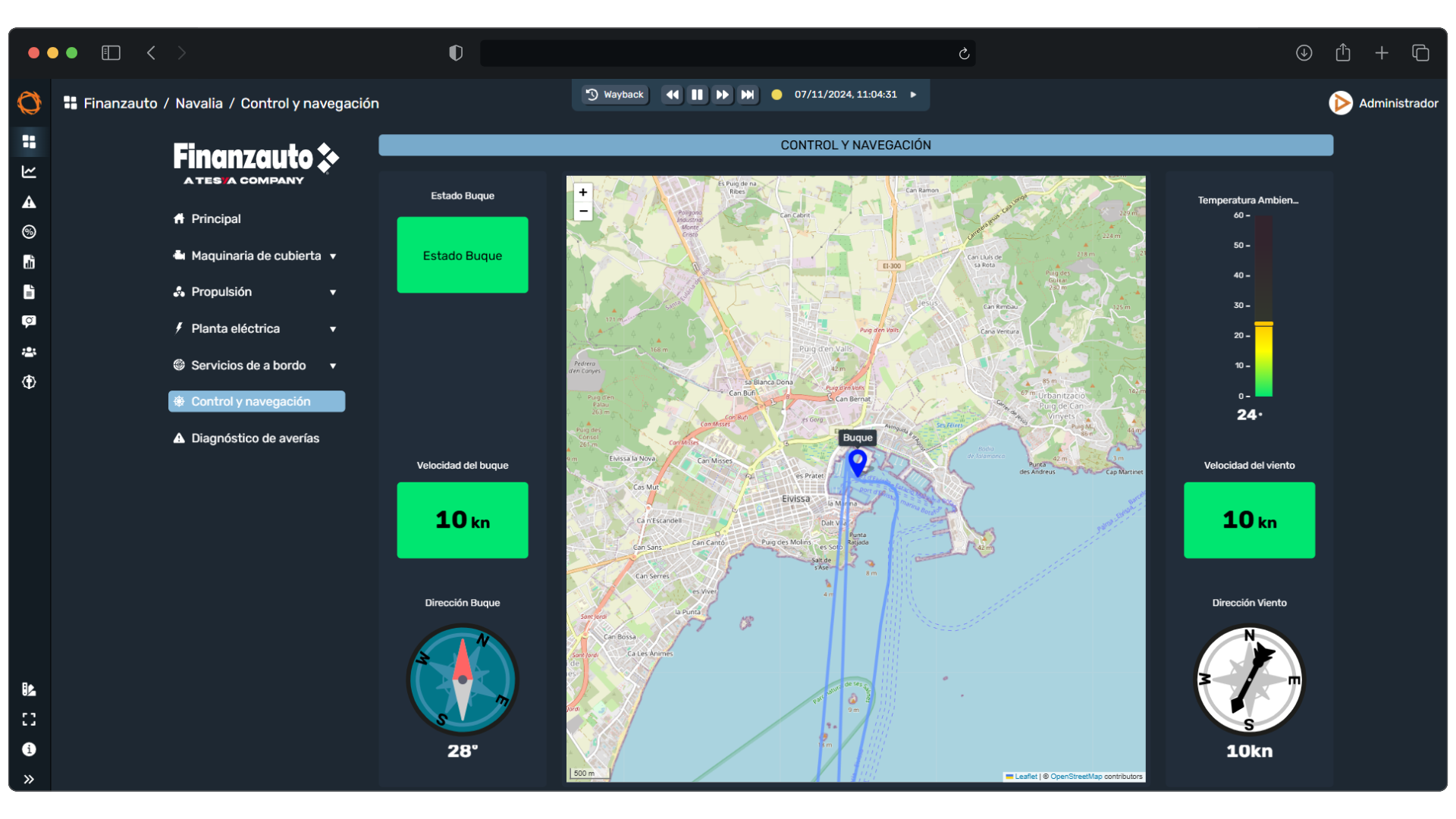

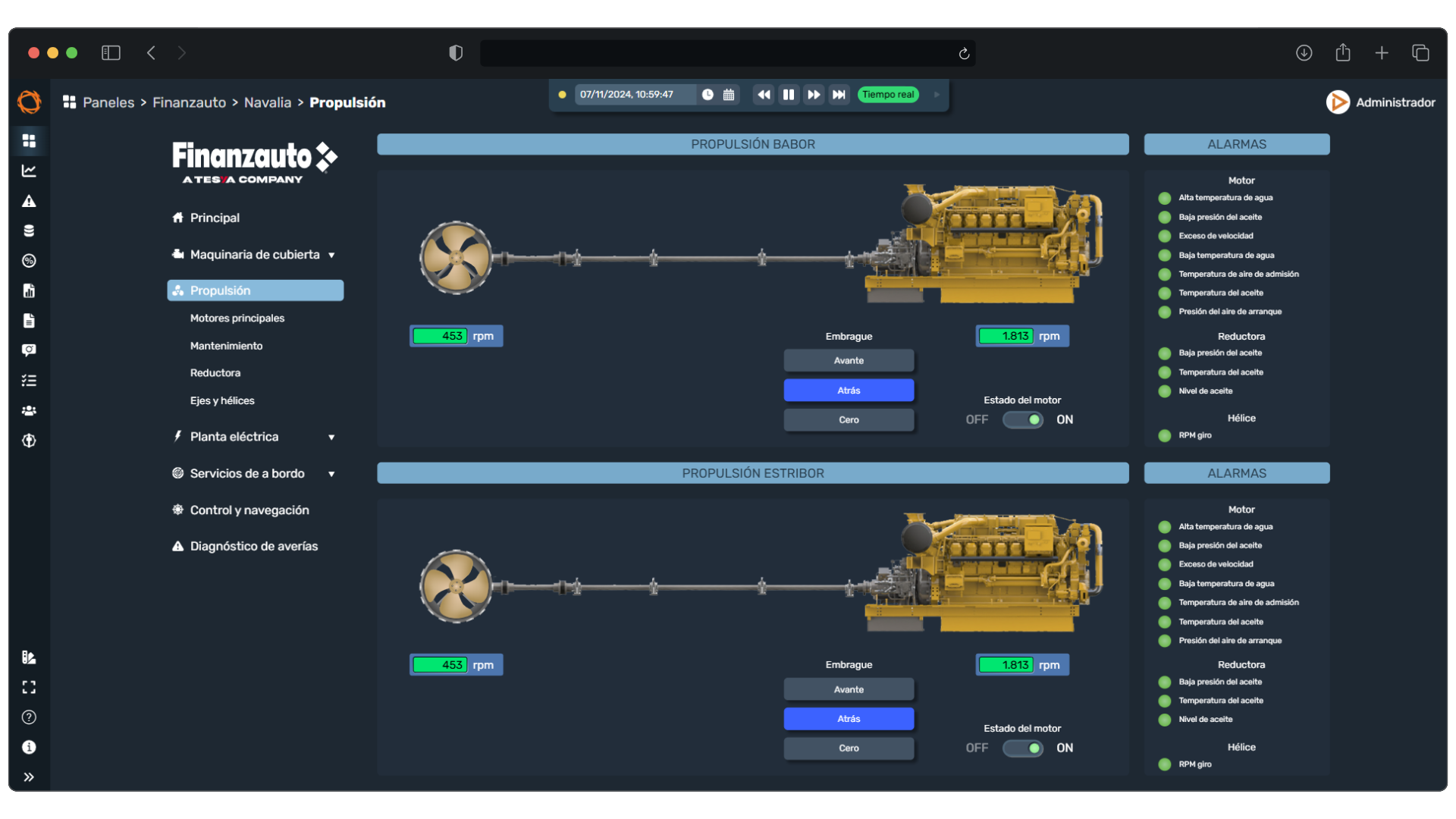

Connected and more profitable vessels

Integration of propulsion systems, alarms, consumption data, HVAC, and electrical panels to optimize routes, reduce emissions, and prevent failures.

An integrated naval ecosystem

Supporting companies, workshops, suppliers, and certification bodies work with reliable data that reduces timelines, prevents errors, and improves final quality.More agile shipyards and full project control

A shipyard is not just a factory: it is an industrial city in constant motion. With our platform, every part of the process—from material arrival to final vessel delivery—can be precisely monitored, automated, and documented.

01.

More precise naval manufacturing

Digitalization turns a shipyard into a coordinated environment where every weld, assembly, and material movement is recorded, anticipating errors and improving execution timelines.

02.

More efficient and safer fleets

Connected vessels enable monitoring of consumption, alarms, and critical systems to optimize routes, ensure regulatory compliance, reduce emissions, and maintain continuous operability.

03.

True predictive maintenance

Continuous monitoring and data analysis make it possible to anticipate failures in propulsion, electrical panels, auxiliary machinery, or navigation systems before they impact operations.

04.

Frictionless collaboration across the naval ecosystem

Supporting companies, workshops, suppliers, electrical integrators, maintenance teams, naval engineering, technical inspection, and certification bodies—all are part of a shared ecosystem.

Success stories

Contact

Contact us at any time to receive more information about our products, services, solutions, and technical support.

This is what will happen next:

Needs analysis

We will contact you to understand your requirements and assess opportunities for improvement in your operations.

Action plan

Our team of specialists will work closely with you, offering recommendations and solutions to optimize the productivity and efficiency of your business.

Final proposal

We will provide you with a detailed action plan, including costs, delivery times, and a complete overview of the improvements it will bring to your assets.