Petrochemical Sector

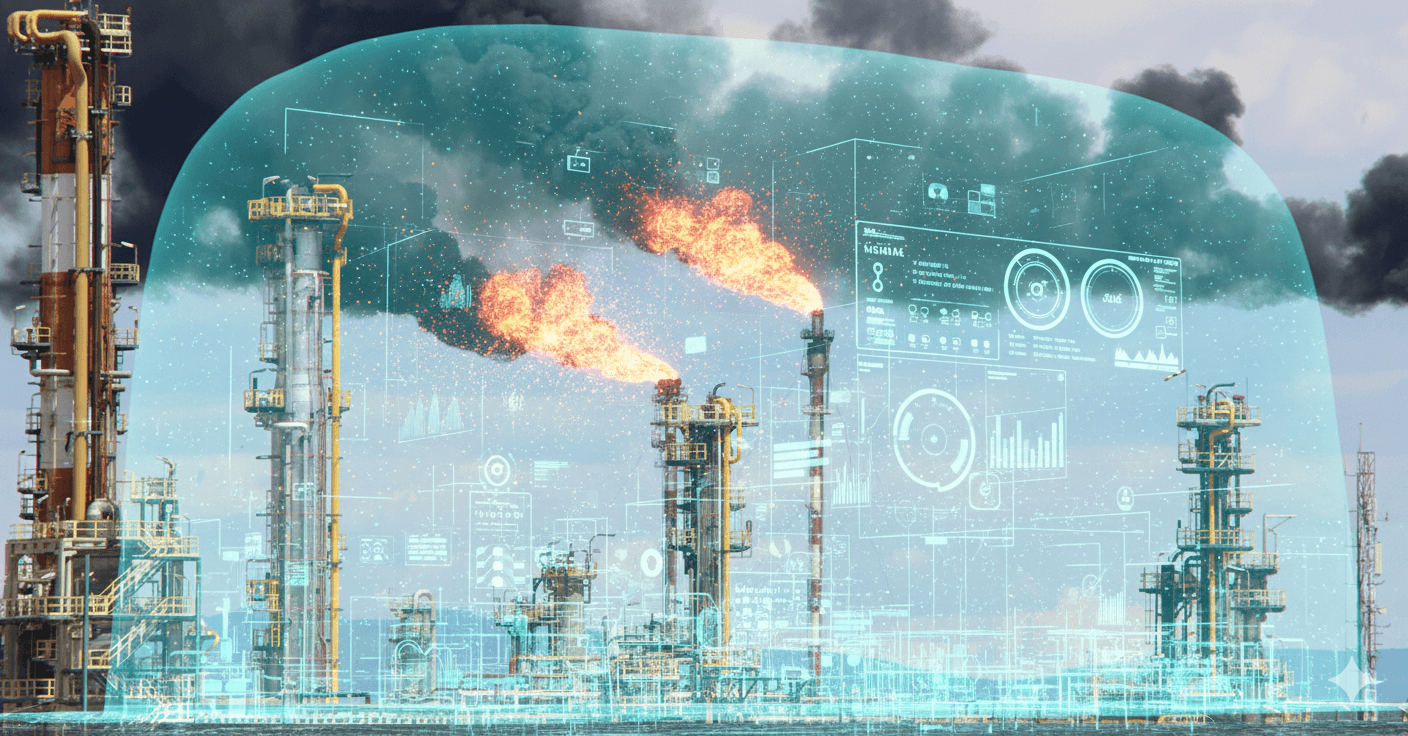

Digital Transformation for Safer, More Efficient, and Connected Plants

At Surcontrol, we help petrochemical plants, refineries, and process operators turn their facilities into smart environments. We integrate advanced sensors, robotics, real-time analytics, and predictive models to create an ecosystem where every unit—compressors, furnaces, tanks, loading lines, or steam networks—operates connected, anticipating failures and optimizing performance.

Connected Process Ecosystem

The plant operates in an integrated way: cracking, compressors, furnaces, and pumping are connected and monitored in real time.

Automation and Advanced Control

SCADA, PLC, DCS, and SOA architectures that enable safe, flexible operation with minimal manual intervention.

Predictive and Operational Stability

Predictive models and advanced diagnostics to anticipate failures, reduce consumption, and improve stability under critical conditions.How We Drive Operational Advantage

We integrate critical technologies to maximize the performance of every process unit: advanced control, sensors, robotics, and predictive systems that enable safe production, fewer shutdowns, and lower environmental impact.

01.

Advanced Process Control (APC)

We adjust critical operations in real time to maximize performance and minimize deviations.

02.

Intelligent Automation

Design and integration of control systems, SCADA, PLCs, and SOA architectures for flexible and safe plants.

03.

Industrial and Mobile Robotics

Robots for inspection, repetitive tasks, ATEX environments, and operations in hazardous areas.

04.

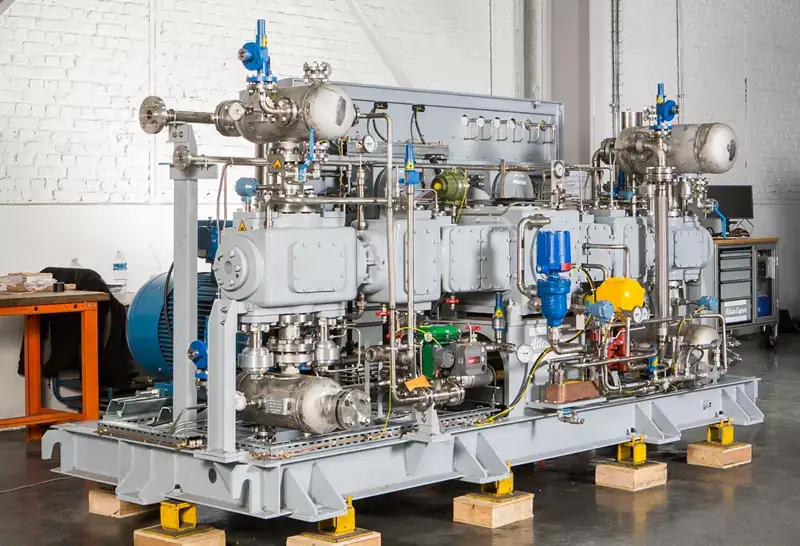

Comprehensive Asset Monitoring

Sensors, industrial IoT, and equipment health systems for turbomachinery, furnaces, heat exchangers, and pumps.

05.

Energy and Emissions Management

Solutions to monitor, reduce, and report consumption, leaks, flaring, and environmental footprint.

06.

Total Interoperability

Integration with DCS, LIMS, ERP, EAM/CMMS, and corporate platforms.

Differentiating Advantages for Operations That Cannot Fail

We enhance the efficiency, safety, and sustainability of each facility through advanced technology, predictive analytics, and engineering focused on tangible results.

01.

Enhanced Safety

By automating critical tasks and using predictive models, operators work with more accurate information and under safer conditions.

02.

Guaranteed Operational Continuity

Digital twins and advanced analytics anticipate failures in key equipment, preventing unplanned shutdowns and extending the plant’s lifespan.

03.

Cost and Waste Reduction

Full process visibility reduces energy consumption, raw material losses, and downtime.

04.

Quality and Regulatory Compliance

360° process traceability: from raw materials to the final product, including emissions, safety, and audits.

05.

Flexibility for the Energy Transition

We help adapt existing facilities toward cleaner models: hydrogen, bioproducts, CO₂ capture, and energy efficiency.

Real Use Cases

Projects Developed in the Petrochemical Sector

Solutions applied to supply, tank monitoring, valves, and pumping stations.Complete Station Control

We detect leaks in seconds by analyzing pressure, flow, and temperature variations, triggering alarms and automatic shutoffs that drastically reduce environmental impact and operational costs. We monitor tanks, valves, and the entire station from a unified panel, automating filling and alerts to ensure safer, more efficient, and fully controlled operations. View Case DetailsSuccess stories

Contact

Contact us at any time to receive more information about our products, services, solutions, and technical support.

This is what will happen next:

Needs analysis

We will contact you to understand your requirements and assess opportunities for improvement in your operations.

Action plan

Our team of specialists will work closely with you, offering recommendations and solutions to optimize the productivity and efficiency of your business.

Final proposal

We will provide you with a detailed action plan, including costs, delivery times, and a complete overview of the improvements it will bring to your assets.