Critical Application Areas in Aerospace Engineering

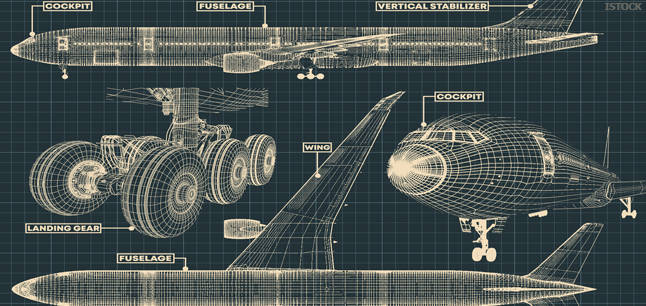

Digitalization and robotics are strategically applied to control minimal tolerances and the highest quality standards throughout an aircraft's lifecycle.

01.

Critical Processes Requiring Absolute Precision

Advanced digitalization and robotics coordinate complex manufacturing, assembly, and maintenance processes with millimetric precision, ensuring efficiency, safety, and full traceability.

02.

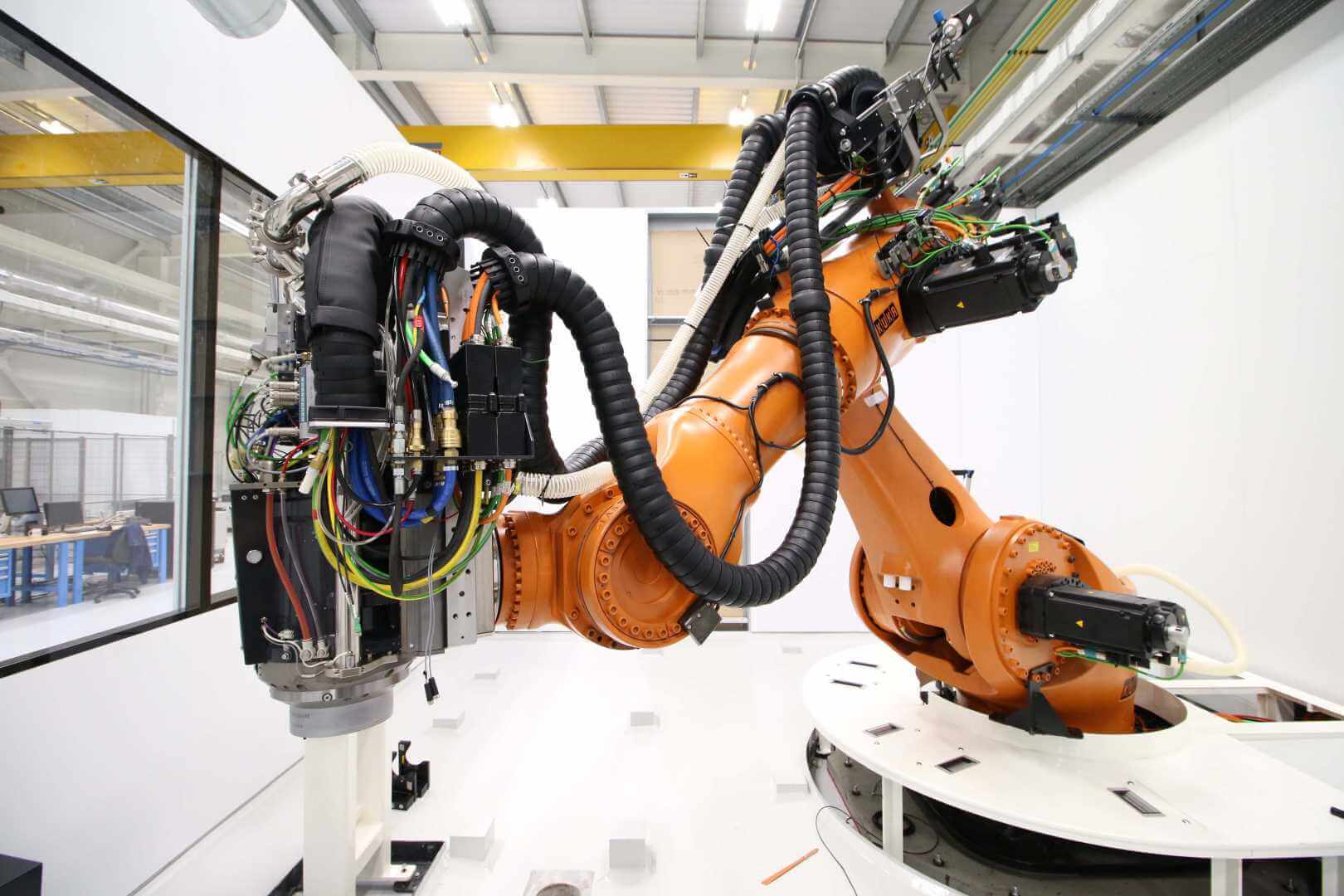

Robotics Applied to Optimize Manufacturing

Industrial robotics applied to aerospace manufacturing increases productivity, reduces human errors, and ensures consistency in every component.

03.

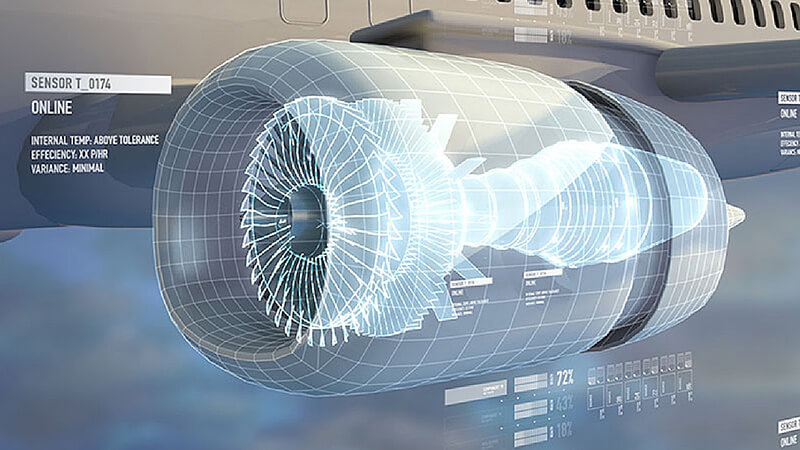

Digitalization and Predictive Maintenance

By integrating sensors, monitoring platforms, and digital twins, it is possible to anticipate failures in aircraft, engines, or critical systems, plan maintenance, and optimize resources.

04.

Full Traceability and Quality Control

Every operation is recorded and accessible in real time, ensuring transparency, compliance with standards, rapid deviation detection, and advanced analysis capabilities to continuously improve processes.

Robotics and Digitalization in Critical Environments

High-Precision Processes Optimized with Intelligent Automation

Industrial robotics, combined with digital platforms and digital twins, enables execution of repetitive and critical tasks with absolute accuracy, reduces human errors, documents every operation in real time, and anticipates failures before they impact production. This multiplies quality, accelerates manufacturing, and ensures safety in every flight or launch.

Automated Assembly with Millimetric Precision

Specialized robots perform welding, screwing, adjustments, and structural assemblies with perfect repeatability, reducing errors and increasing consistency in fuselages, wings, and electronic systems.

Real-Time Control of Every Critical Process

Sensors and digital systems record every operation, torque, or inspection, enabling potential failures to be detected before they occur and ensuring full process traceability.

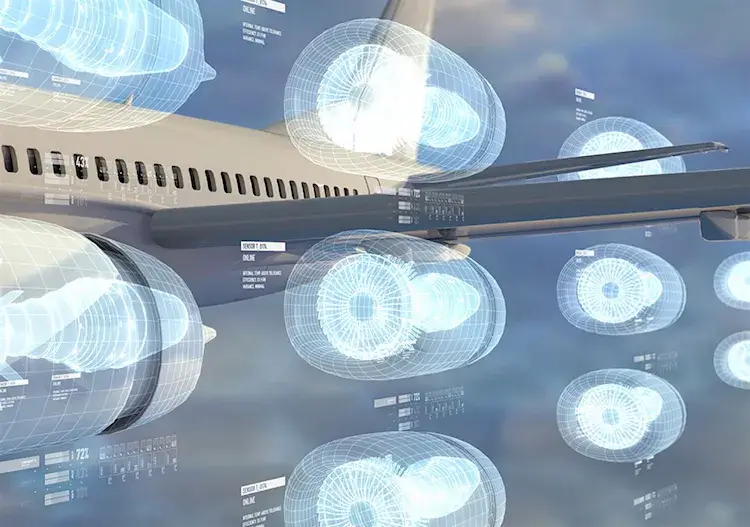

Digital Twins to Anticipate Failures and Optimize Resources

Using digital models of aircraft, engines, and critical systems, it is possible to foresee issues, plan maintenance, and reduce downtime, ensuring maximum operational availability.Success stories

Contact

Contact us at any time to receive more information about our products, services, solutions, and technical support.

This is what will happen next:

Needs analysis

We will contact you to understand your requirements and assess opportunities for improvement in your operations.

Action plan

Our team of specialists will work closely with you, offering recommendations and solutions to optimize the productivity and efficiency of your business.

Final proposal

We will provide you with a detailed action plan, including costs, delivery times, and a complete overview of the improvements it will bring to your assets.